The Effect of Using Micro-Sio2 with Converter Slag of Esfahan Steel Company on Concrete

Fatemeh Sayyahi1 * and Ali Heidari 1

DOI: http://dx.doi.org/10.12944/CWE.10.Special-Issue1.61

This experimental study examined the properties of concrete with different amounts converter slag of Esfahan Steel Company. The experiment investigated properties of concrete containing converter slag with micro-SiO2 and the simultaneous effect of the materials. The results show that the slag has been pozzolanicity to (until) 20% of using in concrete did not have adverse effects on the properties of concrete. Also the effect of the simultaneous use of converter slag and micro-SiO2 is twice and micro-SiO2 can cover the defects caused by the use of slag very well. The results indicates that the use of micro-SiO2 and slag favorable effect on the strength of certain ages.

Copy the following to cite this article:

Sayyahi F, Heidari A. The Effect of Using Micro-Sio2 with Converter Slag of Esfahan Steel Company on Concrete. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). DOI:http://dx.doi.org/10.12944/CWE.10.Special-Issue1.61

Copy the following to cite this URL:

Sayyahi F, Heidari A. The Effect of Using Micro-Sio2 with Converter Slag of Esfahan Steel Company on Concrete. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). Available from: http://www.cwejournal.org/?p=9434

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2015-03-21 |

|---|---|

| Accepted: | 2015-03-30 |

Introduction

Regarding that annually, in our country about seven million tons of steel and iron and rolled steel pipe is produced, and by considering the fact that along with the production of every ton of steel, 300 kg or a ton of slag will be produced, the importance of this secondary product in other industries will be revealed. Scientific studies on the use of slag in concrete indicates that the powder of this waste can be used in making concrete as a substitute of cement and its Granular form of slag can be used as the gravel and light sand in producing concrete. Much research has been done to find a permanent solution for applying slag in other industries, such as trying to reform and neutralize acid soils in agricultural (Geiseler., 1996), (Torkashvand., 2012), Also researchers in the department of Civil and road, use this material as the coarse component asphalt and road concrete because of the good mechanical properties and low price. Of course the existence of high levels of free lime in steel slag composition, has caused a volumetric instability that limits its usage for this purpose(. Zein Aldin., 2012), (Motz et al., 2001), (Tsakirdis et al., 2007). Always in iron and steel industry some by-products are generated. Furnace slag is a production of the steel industry. With the increasing development steel production in the world, furnace slag production is increasing also (Gielen et al., 2001), Slag, a non-metallic material is a byproduct in the production of metallic materials. Converter slag (BOFS) is a material produced during the refinement of crude steel in the converter. The rate of production is about 20-10% by weight of steel production that due to the continuous production of this material, and lack of consumption, Environmental problems and the accumulation of iron and steel plants has been created (Kourounis et al., 2007), Converter slag or the basic oxygen furnace slag, a waste and by-product produced in the furnace steel converter is non-metallic in nature. In this type of slag during in conversion of pig iron to steel during its bellows oxygen is produced. In Esfahan Steel factory, converter slag produced in the cauldron after cooling crumbles in the local weather station is moved to the ponds converter. The main focus of this research, converter slag, has been under several studies to which some of them will be referred in this paper subsequently. In 2002, a survey of steelmaking slag in Turkey, experiments were performed to replace this type of slag in cement, Based on its results, the best value for the replacement of steel slag of Turkey in cement is up to 30% (Altun et al., 2002), In another research, the converter slag was used as coarse aggregate in road construction, Later it was realized that because of the existence of large amounts of lime stone in slag, uncontrolled expansion has occurred. Due to the utilization of coarse aggregate in the samples great stress that causes cracks and, therefore, were demolished (Jukes et al., 2003), (Heribeert et al., 2004). Then the converter slag was used as filler in concrete. The results showed that the slag granulation improves stability and physical and mechanical properties of concrete, because in this case the phase of this material is more active and Results in the improvement of the stability and strength of concrete. However if, the slag is not granulated it can be used as filler (Mooserberg et al., 2004). In another research, cooled converter slag in air. Research showed that the converter slag of France, the hydraulic properties of this slag is weak and lacks any pozzolanicity (Mahieux et al., 2009). In Iran the converter slag of Esfahan Steel Company is used in the base and sub base road superstructure. The results showed that this slags have good durability and reliability, high toughness, can be used in different climatic conditions and high load capacity and the possibility of their applicability in the construction of the base and sub-base layers, asphalt and concrete pavements, are high (Ameri et al., 2012). The effects of different amounts of slag powder instead of Portland cement on concrete properties were investigated (Karbati Asl., 2012). The results obtained from the experiments showed that replacing approximately 25-15% of slag instead of cement is enough to produce concrete with good performance and satisfactory strength. Moreover, by increasing slag powder instead of Portland cement, slag cement shrinkage and concrete strength made with the slag showed an increase in resisting against the sulfate attack.

However, no study has been done on the converter slag for various values of replacement. Also the simultaneous effect of this material with micro-SiO2 has not been investigated. In this experimental research, the convertor slag was first replaced the 10 to 40 percent of the cement; then, after studying the properties of the concrete, the simultaneous effect of using 5 to 15 percent micro-SiO2 and 10 to 40 percent slag instead of cement is discussed.

Materials and Methods

Aggregate

The sand and gravel used in this research was supplied by mines in Shahrekord (Iran). Materials had an appropriate size and were continuous shape, and fineness module was 2.9. The gravel had a graduation from 4.75 to 12.5 mm and water absorption rate was 0.5%.

Cement

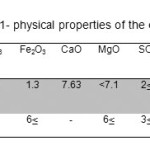

Portland cement Type I was used, and Fineness of cement was 425 (kg/m3). Its physical properties shown in Table 1.

|

Table 1: Physical Properties of the Cement Click here to View table |

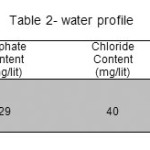

Water

The water used in this experimental study was taken from Shahrekord, Iran. The profiles of the water are shown in Table 2.

|

Table 2: water profile Click here to View table |

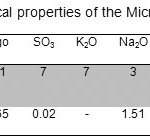

Slag and micro-SiO2

Slags using in this study were converter slag of Esfahan Steel Company. Cracked pieces of slag wastes were crushed by a jaw crusher. At the laboratory scale, the slag wastes were milled with an air jet mill to obtain slag powder. The resulting powder were sieved through a 75-µm (200 mesh) sieve. The micro-SiO2 was in powder form containing silicon dioxide with an average of 93 percent. The physical and chemical properties of cement and micro-SiO2 are given in Table 3.

|

Table 3: physical properties of the Micro-Sio2 and slag Click here to View table |

Super-Plasticizer

In this experimental study, because of using micro silica and nano silica and high water absorption, Plasticizer should have been used. The Plasticizer is POWER PLAST.SM. Features of the Plasticizer was in accordance with the standard ASTM C 494-81 TYPE F. The properties of the super plasticizer used in the study were a PH of 5, a dark-brown color, a specific gravity (g/cm³) of 1.20.

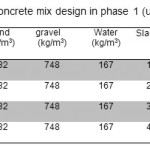

Mix Design

Two phase is considered to do the tests. In the first phase converter slag by amount of 10, 20, 30 and 40% is used as cement replacement (table 4). In The second phase to measure the interactional effect of micro-SiO2 with converter slag, amount of used micro-SiO2 are 5, 10 and 15% as replacement of cement in company of 10, 20, 30 and 40% amount of slag and their simultaneous effect on concrete is investigated (table 2). Finally, some of the mechanical properties such as compressive strength at ages 7, 28, 56 and 90 days old, flexural and tensile strength at 28 days and the water absorption were measured at 28 days. In order to determine compressive strength, cubic molds (10×10×10 cm) were used. Moreover, flexural strength was obtained using prismatic molds (4×4×16 cm) while tensile strength was obtained using cylindrical molds with diameter of 15 cm and height of 30 cm. The concrete mixtures were mixed in accordance with ASTM C192 in 120 litre drum mixer. The test specimens were cast in steel molds (cubic, prismatic and cylindrical molds) and compacted on a vibrating table. After approximately 24 hours, the specimens were removed from the molds. The concrete specimens were cured in water at 20ºC in cure tanks until the time of testing. Casting, compaction, and curing were accomplished according to ASTM C 192. For each mix, cubic samples were tested to determine the compressive strengths at 7, 28, 56 and 90 days of curing. Moreover, prismatic and cylindrical samples were tested to determine the flexural strength and tensile strength at 28 days of curing. The Super plasticizer admixture was used in various amounts to maintain the workability of the fresh concrete. The compressive strength for each mixture was obtained from an average of three cubic specimens. A 2000-kN capacity uniaxial compressive testing machine was used to test the specimens. In the nomination, M represents micro-SiO2, Sco represents the converter slag and the number written in front of these represents the percentage of cement replacements.

|

Table 4: Concrete mix design in phase 1 (unit: kg/m3) Click here to View table |

|

Table 5: Concrete mix design in phase 2 (unit: kg/m3) Click here to View table |

Results

Compressive Strength

The compressive strength of the samples of the first and second are demonstrated in Figure 1 and Figure 2-5, respectively. According to the figures, compressive strength of samples with increasing amounts of slag, is reduced. The reduction of strength of the samples decreased with increasing their ages which confirms the pozzolanicity of the converter slag. The graphs indicate that the older the age of the samples containing higher percentage of slag, the more the strength of them. In the case of 7-day samples, BOFS do not demonstrate pozzolanic activity and only acts as a filler. However, as its age increases, the pozzolanic activity of BOF is started. By increasing amount of slag from 10% to 20% the compressive strength increased 4.61,0.81, 1.9 and 3.6 in 7, 28, 56 and 90 days respectively and then the compressive strength decreased by increasing the amount of slag. In Sco30 sample, a sudden decrease in compressive strength is seen that is conspicuous at the early ages. by increasing in slag to 40%, a slight decrease is observed. With the increase in the amount of slag of 50% another jump in strength is observed. There was a direct connection between the percentage of growth in strength of concrete and the use of slag resulting from the function of the slag at the older ages and lack of proper functioning at lower ages.

|

Figure 1: The Compressive Strength of samples Click here to View figure |

For the second phase samples (fig 2-5), in all graphs, micro-SiO2 at all percentages and in all samples results in significant growth of the compressive strength of concrete, so that all of the samples using micro-SiO2 have higher strength than concrete containing slag. According to figures of this phase, increasing Slag to a degree of 20% in all Samples and increasing micro-SiO2, at the same time, causes the compressive strength to increase on the one hand and adding more slag, decreases the strength on the other. In this case, the highest rate of the compressive strength is due to the use of 20% slag, 5, 10 and 15% micro-SiO2. Furthermore, the lowest strength is related to use of 40% slag, 5, 10 and 15% micro-SiO2. Figures 2 to 5 show and, also, compare the different states of micro-SiO2 compared to the control concrete containing slag. At the age of 7, 28, 56 and 90 days, in all cases, samples containing 5, 10 and 15% micro-SiO2 and slag have higher compressive strength compared to non-micro-SiO2 samples. Adding micro-SiO2 to a degree of 5%, the compressive strength increased and then a further increase in the amount of micro-SiO2 to slag (30 to 40%) the final compressive strength decreases. In other ages, in all samples, samples containing micro-SiO2 causes the compressive strength to grow compared to the control sample without micro-SiO2. The maximum compressive strength belonged to the samples containing 20% slag, 10%, and 15% micro-SiO2, respectively. At the age of 7 days, by increasing micro-SiO2 with 10 and 15 percent of all cases compared to non-micro-SiO2 samples have more compressive strength to some extent. Also, with the samples growing older, the compressive strength in 7, 28 and 56th increases. In samples containing 20%, 30% and 40% slag, similar changes to what has been explained above were observed.

|

Figure 2: The Compressive Strength of samples (Micro-Sio2 and 10% slag) Click here to View figure |

|

Figure 3: The Compressive Strength of samples(Micro-Sio2 and 20% slag) Click here to View figure |

|

Figure 4: The Compressive Strength of samples(Micro-Sio2 and 30% slag) Click here to View figure |

|

Figure 5: The Compressive Strength of samples (Micro-Sio2 and 40% slag) Click here to View figure |

Flexural Strength

In figure 6, the results of the samples containing of converter slag were considered as the control concrete and the addition of micro-SiO2 to the slag can be seen in the flexural strength. As the graphs indicate, adding micro-SiO2 to the samples containing slag reduces flexural strength. With the addition of 5% micro-SiO2 , in all samples, in corresponding percentage of slag, the strength changes to a degree of, approximately, 4% and with the addition of 10% micro-SiO2 decrease the flexural strength but the strength is reduced by adding slag. However, the sample containing 15% micro-SiO2 in the samples containing 10% slag, shows 2% growth in flexural strength. The important point in diagram is that the samples containing micro-SiO2 without any additive in a specific phase show reduction in strength compared to their control concrete. Minimum flexural strength belongs to the samples containing 40% slag.

|

Figure 6: The flexural Strength of samples Click here to View figure |

Tensile Strength

Figure 7 shows that the combination of micro-SiO2 with converter slag gives better results than samples with converter slag. In a specific percentage of micro-SiO2, for example 5% of micro-SiO2, with increasing slag, in tensile strength decreases. The maximum of tensile strength belongs to use of 10% converter slag and the minimum tensile strength is related to 40% converter slag, By addition of 5% micro-SiO2 to slag, the samples in the corresponding ages and percentage, 13 and 17% in sample containing 10% and 20% converter slag increases respectively. With the addition of 30% slag, tensile strength decreases about 1%, then sample with 40% slag indicate an increase in strength about 18%.

|

Figure 7: The tensile Strength of samples Click here to View figure |

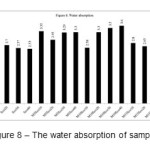

Water Absorption

Water absorption is another parameter that is measured. Water absorption clearly shows the condition of the pores of the concrete appropriately. Water absorption tests were performed on samples of 28 days. The process of water absorption indicates that in samples containing 10% to 20% slag, water absorption decreases and the sample containing 40% slag, water absorption, compared to the sample containing 30% slag, slightly decreases to the extent that the water absorption reaches to 2.49% for samples containing 50% slag. Generally, the use of slag in concrete has a positive effect on water absorption. As Figure 8 demonstrates, in the samples that contain micro-SiO2, by increasing micro-SiO2, water absorption increases, compared to the control sample in corresponding percentage of slag, except for the samples containing 15% micro-SiO2 with 10% and 20% slag. The samples, M5Sco10, M5Sco20, M5Sco30 and M5Sco40 compared to control concrete, in corresponding percentage of slag, have 17.54, 9.25, 28 and 30.43% increasing in water absorption, respectively. M10Sco10, M10Sco20, M10Sco30 and M10Sco40 samples compared to control concrete in corresponding percentage of slag -9.47, 48.14, 36.16 and 42.29% have changes in water absorption, respectively. By adding micro-SiO2 to 15% in slag about 10 and 20%, water absorption decreases and in the samples with slag about 30 and 40% indicated similar results comparing to control concrete.

|

Figure 8: The water absorption of samples Click here to View figure |

Discussion

According to the experiments, the following results were obtained:

Due to the appropriate strength of samples containing up to 20% slag, that their strength was approximately equal to that of control sample at its 90-day, the use of this material can be utilized as a perfect substitute for cement at these percentages. Using 30% the slag has lowered strength of concrete about 10% which compared to the removal of 30% cement is negligible. It seems that the use of this material in range of above 40%, finally, would result in good strength.Water absorption of samples with use of converter slag has decreased. The decreasing of the sample containing 20% slag was higher than the other samples, the water absorption have seen about 5.13% decrease compared to control concrete. Also, by increasing the amount of slag, the decrease in water absorption stopped it began to increases.

The use of micro-SiO2 with slag, has a significant effect on increasing the strength and decreasing the water absorption. In other words, by increasing slag, the effect of higher micro-SiO2 are shown. In samples by lower Percentage of slag, micro-SiO2 has less effect on development of strength.

According to the fast that converter is waste, the only cost of the slag is the expenses related to the collection and milling, in case of mass production, as a result, the production cost of convertor is far less than the cost of cement production.

References

- Geiseler, J. Use of steelworks slag in Europe. Int. J. Waste Management, 16 (1), 59-63 (1996).

- Mohammadi Torkashvand. A. Used converter slag as modifiers and iron fertilizer in acid soils on calcareous soils. The Faculty of Agriculture, University of Esfahan Technology (2000).

- Zein Aldin, H. Design and production of hot mix asphalt concrete slag. Department of Civil Engineering, University of Esfahan Technology (2012).

- Motz, H. and Geiseler, J. Products of steel slags an opportunity to save natural resources. Int. J. Waste Management, 21(3), 285-293(2001).

- Tsakirdis, P.E; Papadimitriou, G.D; Tsivilis, S. and Koroneos, C. Utilization of steel slag for Portland cement clinker production. Hazardous Materials, 152(2), 805-811(2007).

- Gielen, D.J. and Moriguchi, Y. Environmental strategy design for the Japanese iron and steel industry a global perspective. Tsukuba National Institute for Environmental Studies (2001).

- Kourounis, S; Tsivilis, S. Tsakiridis, P.E. Papadimitriou, G.D. and Tsibouki, Z. Properties and hydration of blended cements with steelmaking slag. J. Cement and Concrete Research, 37(6), 815-822 (2007).

- Altun, I. A; and Yilmaz, I. Study on steel furnace slags with high MgO as addictive in Portland cement. Int. J. Cement and Concrete Research, 32, 1247–1249(2002).

- Jukes, L.M. The volume stability of modern steel making slag. Int. J. Mineral Processing and Extractive Metallurgy, 112, 177–197 (2003).

- Heribeert, M. and Kuhn, M. Iron and steel slags as sustainable construction resources and fertilizer. 2nd International Conference on Process Development in Iron and Steel Making, Sweden, 347–358 (2004).

- Mooserberg, B. Steel-slag as filler material in concrete. VII International Conference on Molten Slags, Fluxes and Salts, 385–391 (2004).

- Mahieux, P.Y; Aubert, J.E. and Escadellias, G. Utilization of weathered basic oxygen furnace slag in the production of hydraulic road binders. Int. J. Construction and Building Materials, 23, 742-747 (2009).

- Ameri, M. and shahabi shahmiri, H. Study converter slag characteristics Esfahan Steel Company for use on base and sub-base layers pavement. Journal of Road, 123-126 (2012).

- Karbati Asl, R. The effect different amounts of powdered slag instead of Portland cement as replacement in concrete properties. 3th annual National Conference of concrete (2012).